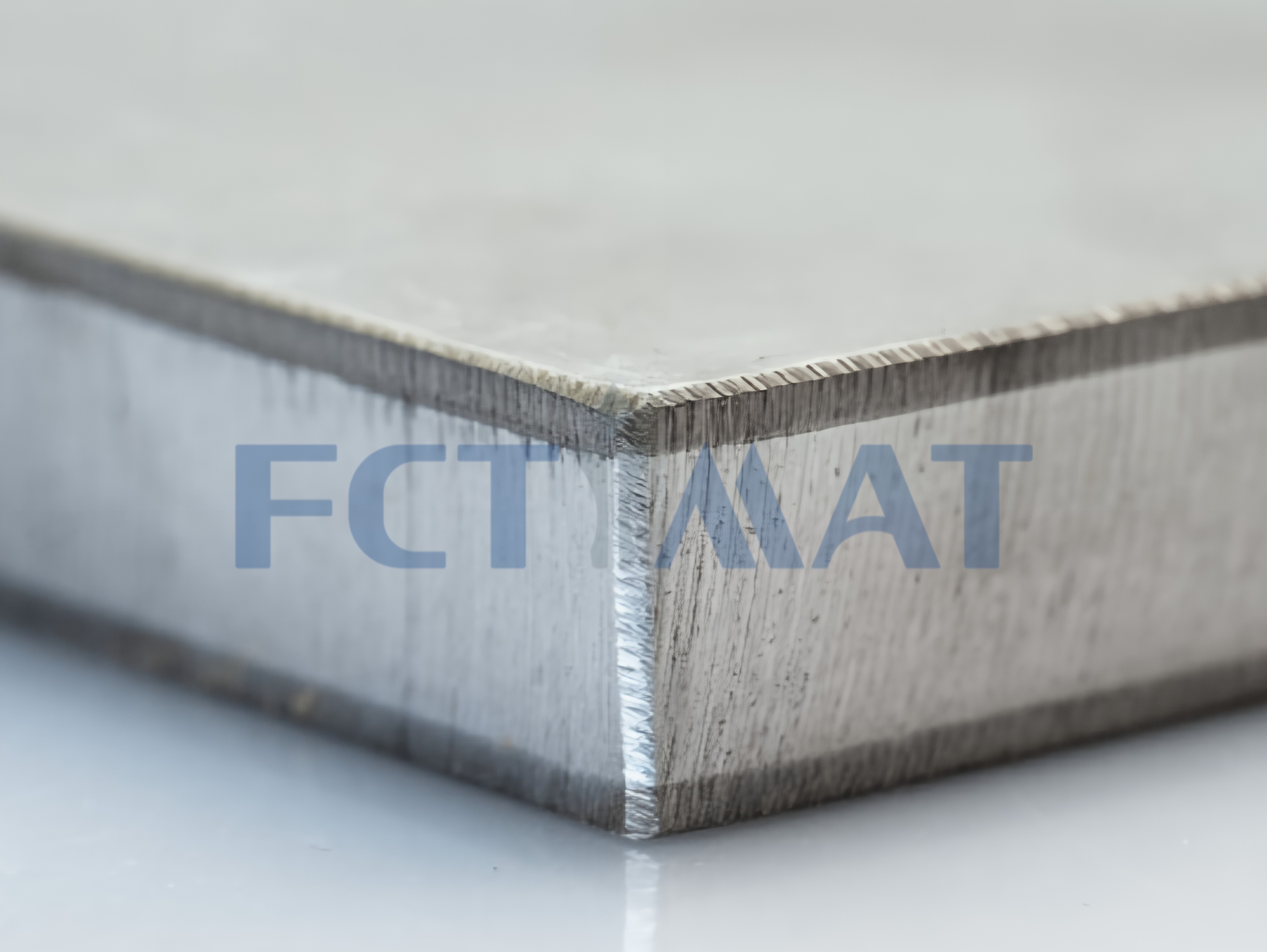

Clad Material

- Commodity name: Clad Material

Email:

Description

FCTIMAT Clad materials integrate the exceptional corrosion resistance and lightweight properties of titanium with the structural strength and cost-effectiveness of base metals such as carbon steel, stainless steel, or nickel alloys. These materials are ideal for industries that demand high performance in harsh environments while optimizing material costs. The standard dimensions are 1300×280×65 mm, with custom specifications available to meet specific requirements, offering global solutions for a wide range of applications.

Currently FCTIMAT focus on Metallurgical CLAD (HRB/Explosion clad).

Category | Details |

|---|---|

Benefits |

|

Titanium Grades |

|

Manufacturing Methods |

|

Industries & Applications |

|

Key Considerations |

|

FCTIMAT Titanium-clad materials offer the perfect balance of performance and cost, making them ideal for industries that demand durability in corrosive or high-stress environments. By leveraging titanium’s superior properties without the full cost of solid titanium, engineers achieve long-term reliability and efficiency.

Partner with a FCTIMAT trusted global manufacturer of Ti Clad Material.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products