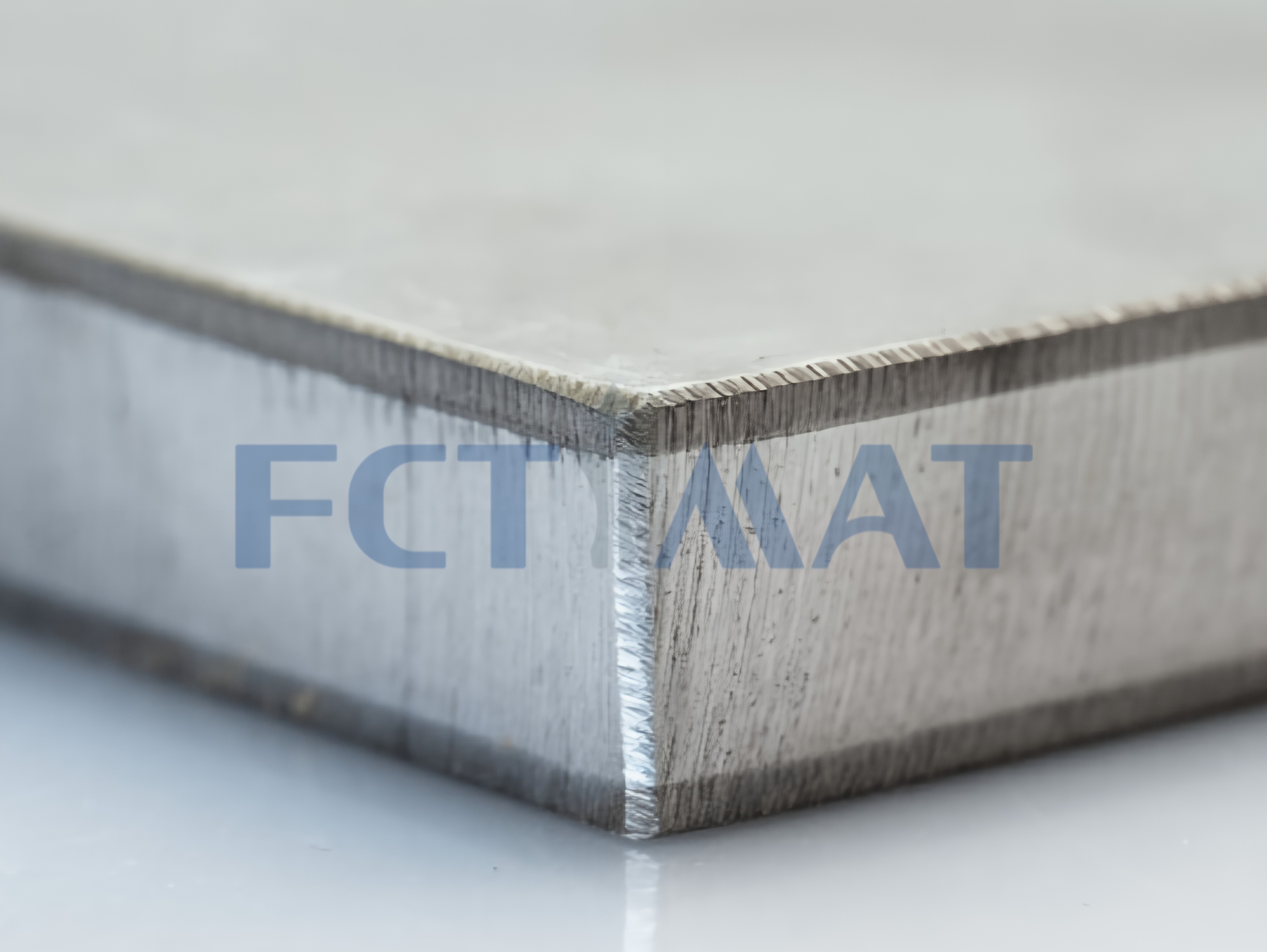

Titanium Ingots

- Commodity name: Titanium Ingots

Email:

Description

FCTIMAT Ti ingots serve as the primary raw material for manufacturing premium titanium components, offering exceptional strength, lightweight properties, and superior corrosion resistance. Produced through advanced vacuum arc remelting (VAR) or electron beam melting (EBM) processes, these high-purity metal blocks ensure consistent quality for critical applications across industries. FCTIMAT Ti Ingots Specification(mm) Φ540~1060. The grades offered are Gr.1, Gr.2, Gr.3, Gr.4, Gr.5, Gr.9, Gr.10, Gr.12, Gr.23, Gr38, Ti6242, Ti6246 etc. Other titanium alloys, such as Ti1023, etc., can be manufactured according to user requirements.

Titanium Ingots Specifications

- Ultra-High Purity - Manufactured under controlled vacuum conditions to eliminate impurities and ensure material integrity.

- Superior Strength-to-Weight Ratio - 45% lighter than steel with comparable (or greater) strength, ideal for aerospace and defense applications.

- Extreme Corrosion Resistance - Resists saltwater, acids, and industrial chemicals, outperforming stainless steel in harsh environments.

- Biocompatibility - Safe for medical implants, surgical tools, and dental devices due to non-toxic, hypoallergenic properties.

Titanium Ingot Grades & Applications

|

Grade |

Composition |

Key Properties |

Primary Uses |

|

Grade 1 |

99.5% Pure Ti |

Highest ductility, excellent corrosion resistance |

Chemical processing, marine components |

|

Grade 2 |

99.2% Pure Ti |

Balanced strength & weldability |

Heat exchangers, medical devices |

|

Grade 5 (Ti-6Al-4V) |

90% Ti, 6% Al, 4% V |

High strength, moderate weight |

Aircraft parts, orthopedic implants |

|

Grade 7 |

Ti-0.2% Pd |

Enhanced acid resistance |

Chemical reactors, pharmaceutical equipment |

|

Grade 23 (Ti-6Al-4V ELI) |

Extra-low interstitial |

Superior fracture toughness |

Spinal implants, trauma plates |

Industries Using Titanium Ingots

- Aerospace - Jet engine components, airframe structures

- Medical & Dental - Bone screws, joint replacements, surgical instruments

- Marine & Offshore - Propeller shafts, subsea valves, desalination plants

- Chemical Processing - Pressure vessels, reactor linings, heat exchangers

- Automotive & Motorsports - Lightweight chassis, exhaust systems, racing components

Production & Quality Assurance

Titanium ingots undergo strict metallurgical testing, including:

- Chemical composition analysis

- Ultrasonic inspection for defects

- Mechanical property verification

FCTIMAT provide certified material test reports (MTRs) to ensure compliance with ASTM, AMS, and ISO standards.

Custom Solutions & Machining

Titanium ingots can be further processed into:

- Billets for forging

- Bars, plates, and sheets

- Precision-machined components

Partner with FCTIMAT trusted global manufacturer & supplier specializing in aerospace-grade, medical-grade, and industrial titanium alloys.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products