Titanium Discs

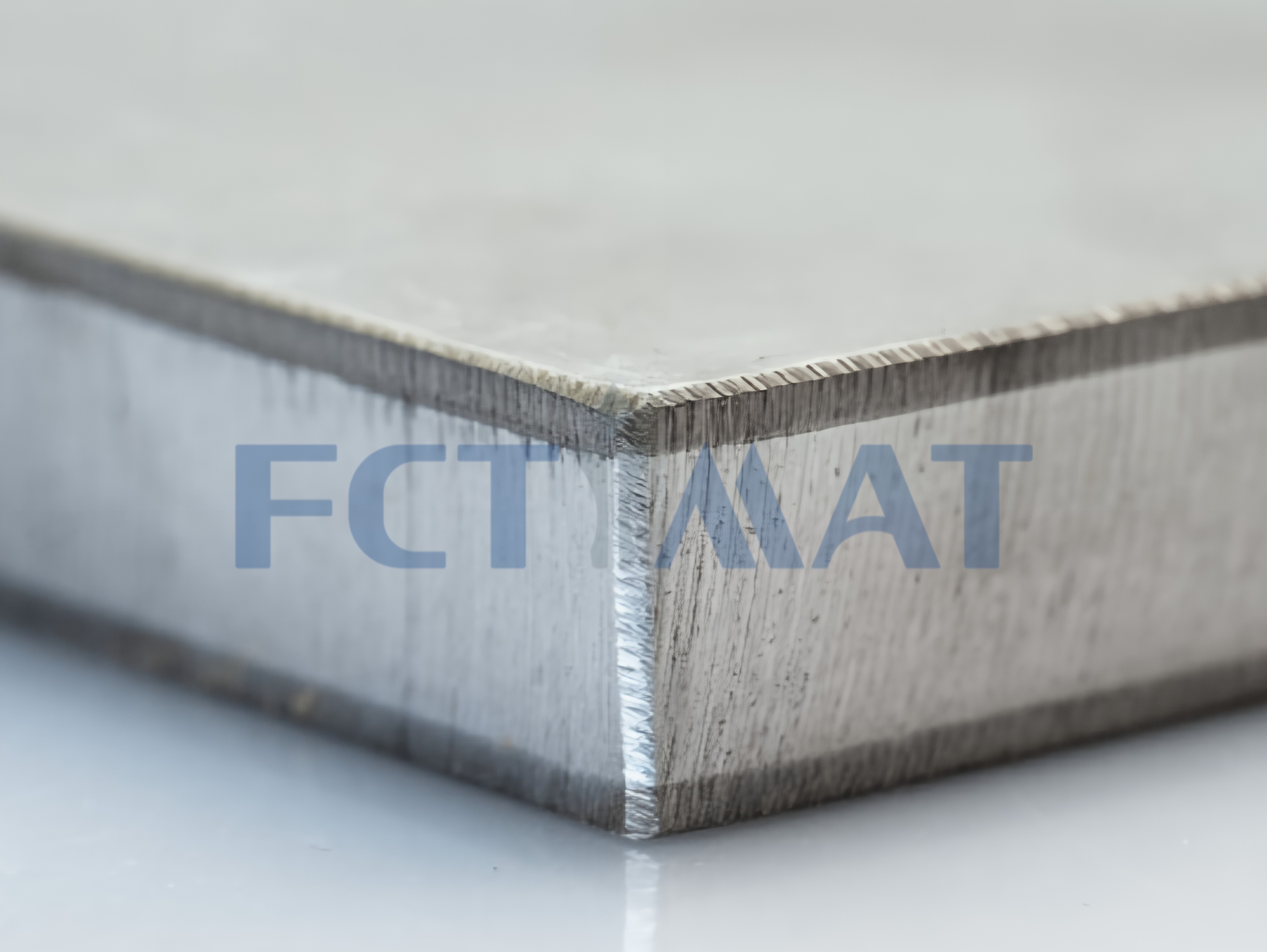

- Commodity name: Titanium Discs

Email:

Description

FCTIMAT Ti discs are precision-engineered components manufactured from pure titanium or advanced titanium alloys, Specification(mm) Φ60~2800×80~500. The grades offered are Gr1, Gr2, Gr3, Gr4, Gr5, Gr9, Gr10, Gr12, Gr23, Gr38, Ti6242, Ti6246 etc. Other titanium alloys, such as Ti1023, etc., can be manufactured according to user requirements, offering exceptional strength, lightweight properties, and corrosion resistance. FCTIMAT Ti discs are widely used in industries where durability and performance are critical.

|

Grade |

Common Name |

Composition |

Key Properties |

Typical Applications |

|

Gr1 |

CP Titanium (Grade 1) |

99.5% Ti |

Highest ductility, excellent corrosion resistance, low strength |

Chemical processing, marine components, heat exchangers, desalination plants |

|

Gr2 |

CP Titanium (Grade 2) |

99.2% Ti |

Balanced strength & ductility, good weldability, corrosion resistance |

Aerospace, medical implants, chemical equipment, marine hardware |

|

Gr3 |

CP Titanium (Grade 3) |

99.1% Ti |

Higher strength than Gr1 & Gr2, moderate formability |

Aerospace structures, chemical processing, surgical applications |

|

Gr4 |

CP Titanium (Grade 4) |

99.0% Ti |

Highest strength among CP Ti grades, good corrosion resistance |

Surgical implants, cryogenic vessels, heat exchangers, industrial components |

|

Gr5 |

Ti-6Al-4V (Grade 5) |

Ti-6Al-4V |

High strength-to-weight ratio, excellent fatigue resistance |

Aerospace (airframes, engines), medical prosthetics, marine, automotive racing |

|

Gr9 |

Ti-3Al-2.5V |

Ti-3Al-2.5V |

Better weldability & formability than Gr5, moderate strength |

Hydraulic tubing, bicycle frames, aerospace ducting, marine components |

|

Gr10 |

Ti-11.5Mo-6Zr-4.5Sn (Beta-C) |

Ti-11.5Mo-6Zr-4.5Sn |

High strength, corrosion resistance, biocompatibility |

Biomedical implants, chemical processing, aerospace fasteners |

|

Gr12 |

Ti-0.3Mo-0.8Ni |

Ti-0.3Mo-0.8Ni |

Enhanced corrosion resistance (especially crevice corrosion) |

Heat exchangers, chemical processing, hydrometallurgical applications |

|

Gr23 |

Ti-6Al-4V ELI (Grade 23) |

Ti-6Al-4V (Extra Low Interstitial) |

Higher purity, improved fracture toughness, biocompatibility |

Medical implants (joint replacements, dental), aerospace critical structures |

|

Gr38 |

Ti-4Al-2.5V |

Ti-4Al-2.5V |

Improved weldability & strength over Gr9 |

Aerospace tubing, hydraulic systems, marine applications |

|

Ti6242 |

Ti-6Al-2Sn-4Zr-2Mo |

Ti-6Al-2Sn-4Zr-2Mo |

High-temperature strength, creep resistance |

Jet engine components, gas turbines, high-temperature aerospace structures |

|

Ti6246 |

Ti-6Al-2Sn-4Zr-6Mo |

Ti-6Al-2Sn-4Zr-6Mo |

High strength, fatigue resistance, heat treatable |

Aircraft landing gear, structural aerospace components |

|

Ti1023 |

Ti-10V-2Fe-3Al |

Ti-10V-2Fe-3Al |

High strength, deep hardenability, excellent forging properties |

Aerospace forgings (landing gear, airframe components), high-stress structural parts |

Features of Ti Discs

- High Strength-to-Weight Ratio - Ideal for aerospace and automotive applications, where reducing weight without sacrificing strength is essential.

- Superior Corrosion Resistance - Resists harsh environments, including saltwater and chemical exposure, making them perfect for marine and industrial uses.

- Biocompatibility - Safe for medical implants, including dental prosthetics, joint replacements, and surgical tools, due to non-toxicity and compatibility with human tissue.

- Heat & Wear Resistance - Maintains structural integrity under extreme temperatures, suitable for aerospace engines and high-performance machinery.

Applications of Titanium Discs

- Aerospace - Used in jet engines, spacecraft, and airframe components.

- Medical & Dental - Essential for implants, bone screws, and dental crowns due to biocompatibility.

- Industrial - Applied in chemical processing, marine hardware, and power generation.

- Automotive & Defense - Enhances performance in high-stress components like valves and armor plating.

Partner with a FCTIMAT trusted global manufacturer specializing in ASTM/ASME compliant Ti Discs for high quality and performance.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products